Single Screw Extruder Gear Units

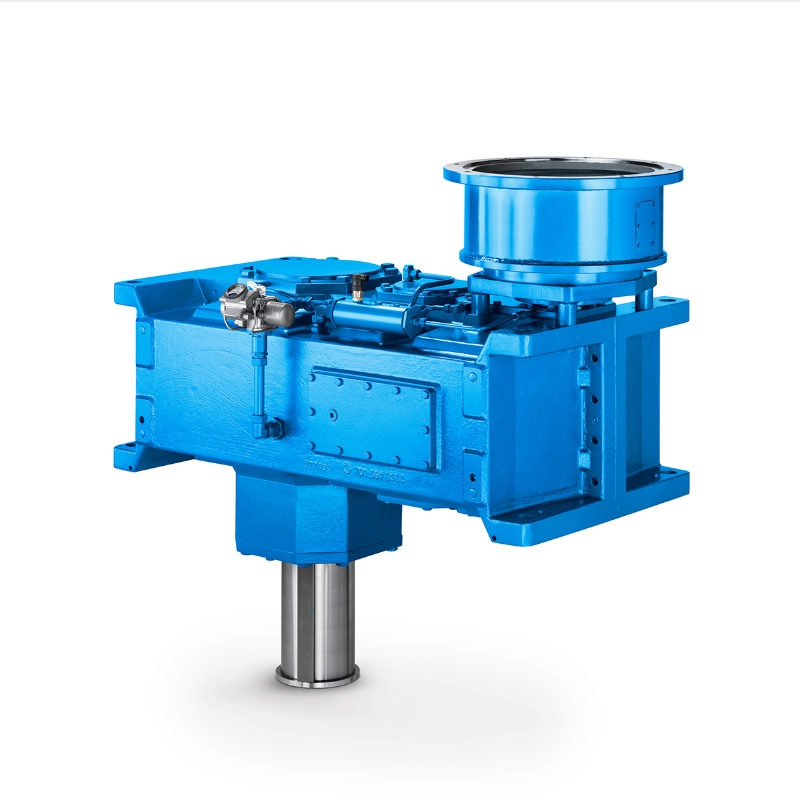

Single screw extruder gear units are core transmission components of rubber and plastic processing equipment, tasked with the key mission of converting the high-speed rotation of motors into low-speed, high-torque output of screws. They directly determine the plasticizing efficiency, material stability and service life of extruders, and are widely applicable to production lines for plastic pipes, films, profiles and other products.

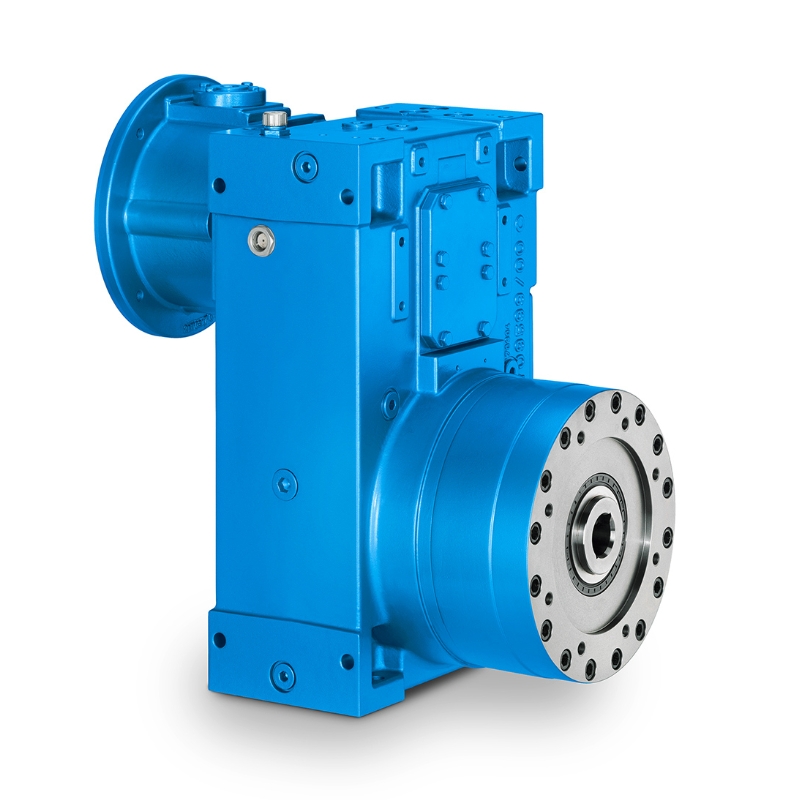

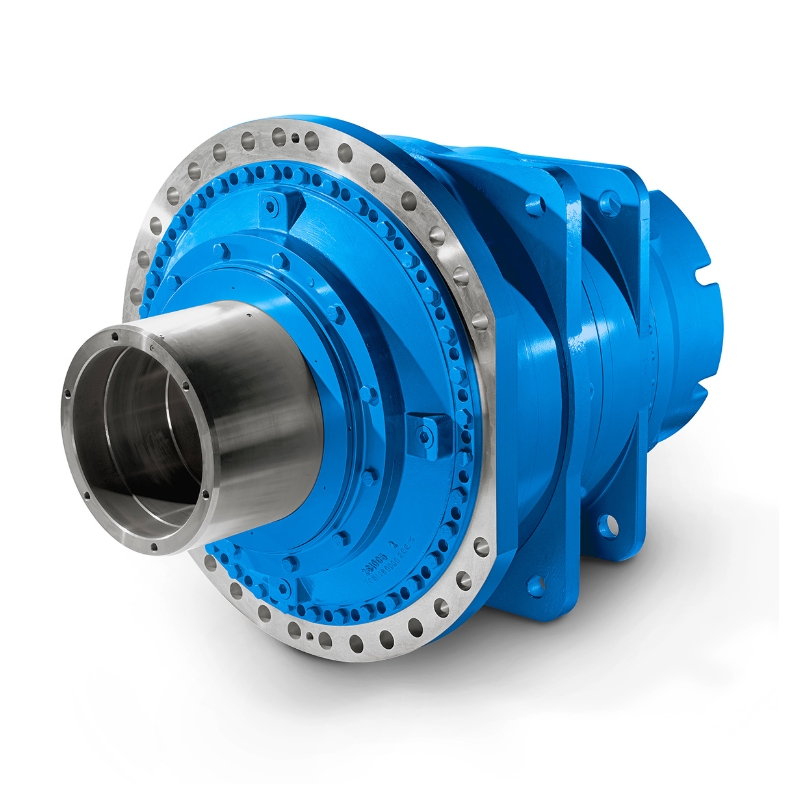

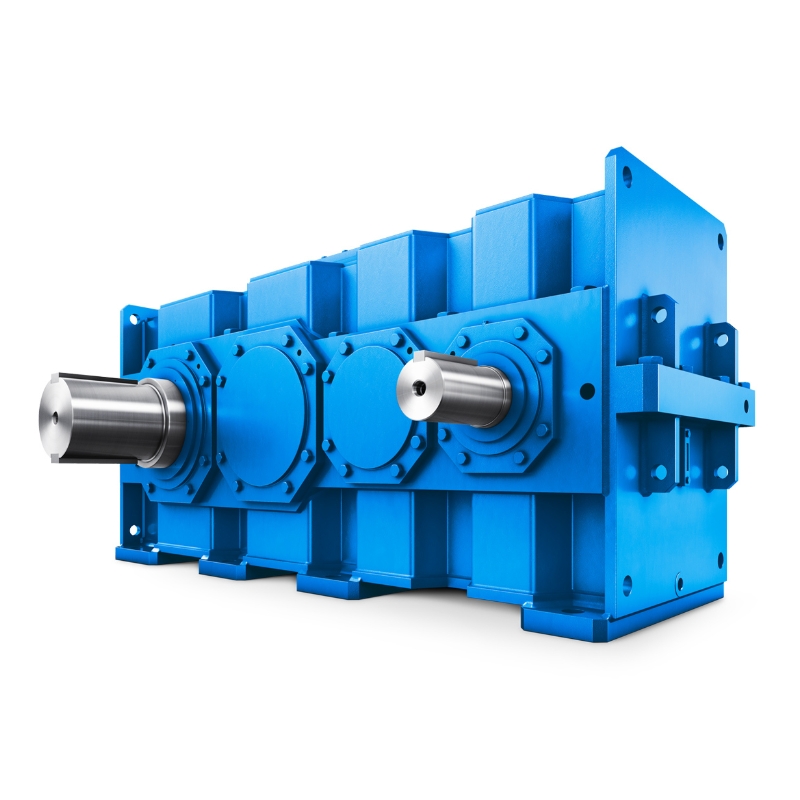

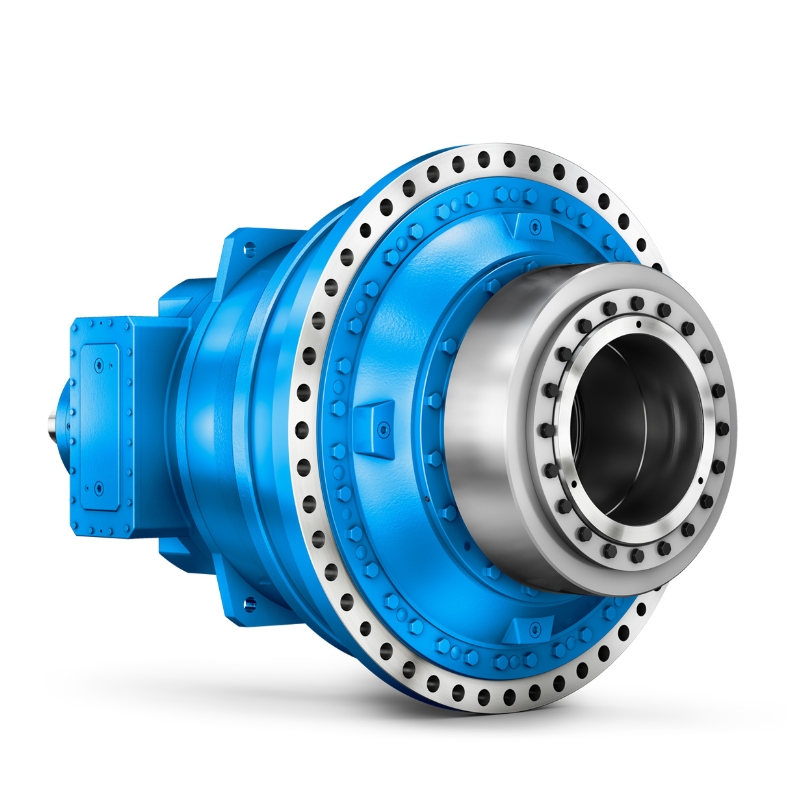

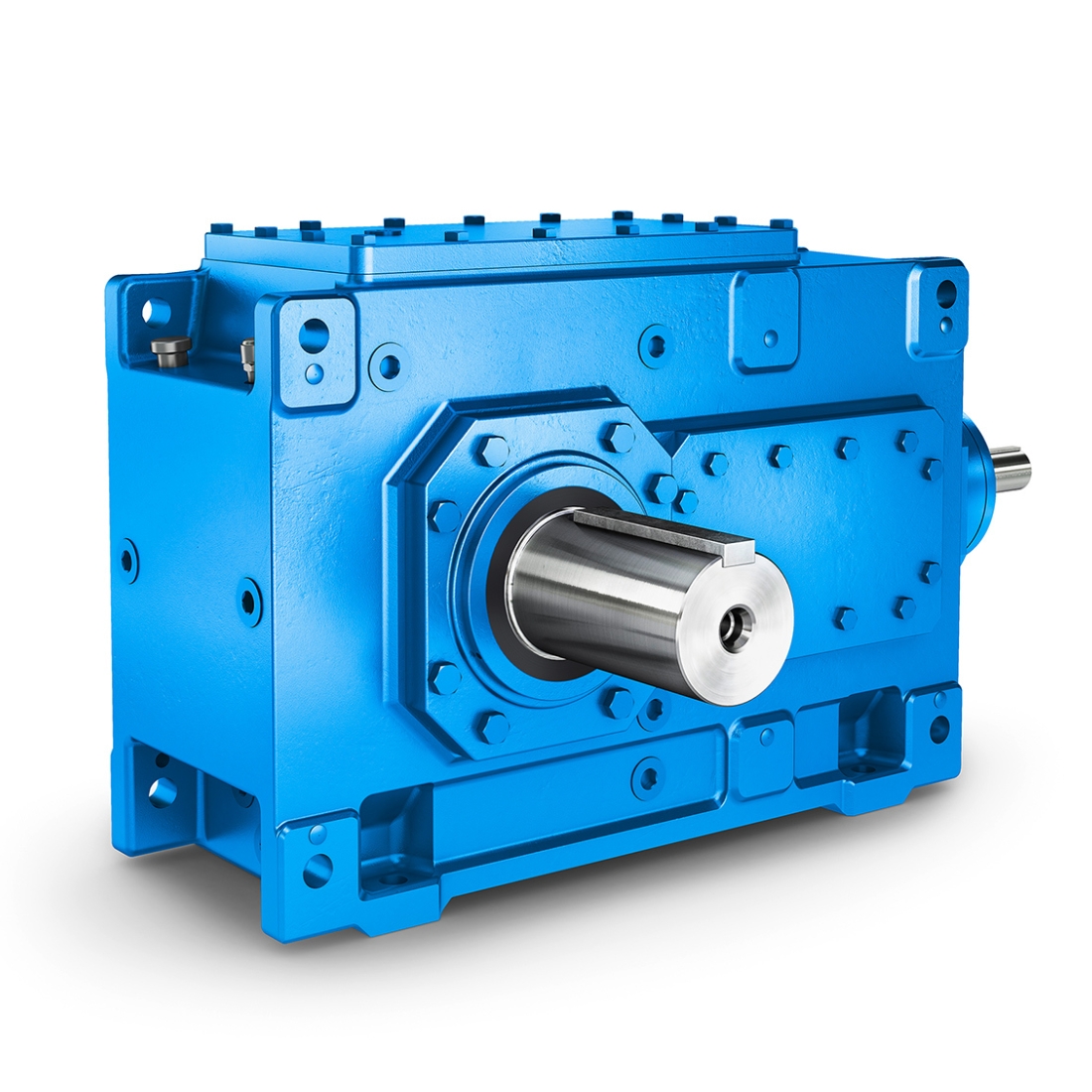

The mainstream structures of such gear units include **hard-tooth-flank parallel axis transmission** and **planetary gear train**. Among them, the ZLYJ series, as an industry benchmark model, adopts high-strength alloy steel gears processed by carburizing and quenching as well as precision gear grinding. The gear accuracy reaches Grade 6 per GB10095-88, with a surface hardness of HRC54-62, featuring both high load-bearing capacity and low noise performance. Through power-splitting design, the planetary transmission structure enhances the load-bearing capacity by 20%-30% compared with traditional parallel axis models, which can effectively withstand impact loads during extrusion and avoid gear failure such as tooth breakage and pitting.

Core technical advantages lie in targeted designs: a large-size thrust bearing is configured at the front end of the hollow output shaft to bear the axial force generated by the screw during operation; integrated water cooling or forced lubrication systems are adopted to adapt to a wide temperature range of -40℃~45℃, ensuring thermal balance in high-temperature plasticizing environments. The transmission efficiency can reach 94%-98.5%, with a reduction ratio range of 18.35-53.6 and a rated power of 22-750kW, meeting the precise requirements for rotational speed and torque in different extrusion processes.

Its modular design is compatible with various lubrication and sealing solutions, and the maintenance-free sealing structure can effectively prevent foreign matter intrusion and lubricating oil leakage. Currently widely used in rubber and plastic processing, biodegradable material production and other fields, high-end models integrated with intelligent sensors in the premium market can realize real-time monitoring of torque and temperature, providing data support for predictive maintenance and facilitating the upgrading of the manufacturing industry towards high efficiency and green development.

FLENDER Reducer Single Screw Extruder Gear Units Models, Weights and Motor Combinations

Note: FLENDER single screw extruder gear units are high-precision hard-tooth-surface transmission components designed for plastic, rubber and chemical single screw extruders. Adopting JB/T8853-2001 and international standards, they feature high-strength alloy steel gears (carburized, quenched and ground, tooth surface hardness HRC54-62) and oversized thrust bearings to withstand axial forces from screws. Weights refer to the gear unit body (cast iron/welded steel housing) and vary by configuration. Motor combinations comply with FLENDER standard matching, covering IE2-IE4 efficiency classes for stable, high-efficiency extrusion processes.

1. H2 SH Series (Compact Helical Gear Units for Small-Medium Extruders)

| Model | Weight | Motor Combination (Power Range) |

| H2 SH 07 A | 0.528kg | IE4 motors (44kW); input speed 1500r/min, uses ISO VG 320 synthetic extreme pressure gear oil, BA5010/BA7300 certified, suitable for small integrated single screw extruders |

| H2 SH 08 B, H2 SH 09 C | 1.2kg-2.8kg | IE3/IE4 motors (22kW-55kW); compact structure, high transmission efficiency ≥95%, suitable for laboratory and small-scale production extruders |

2. HH Series (Heavy-Duty Helical Gear Units for Medium-Large Extruders)

| Model | Weight | Motor Combination (Power Range) |

| B4HH15A, B4HH15C | 520kg-535kg | IE4 high-efficiency motors (75kW-132kW); input speed 1486r/min, reduction ratio 85.65:1, output speed 17.35r/min, reinforced thrust bearings for high axial load |

| B3HH12B, B3HH18D | 380kg-780kg | IE3/IE4 motors (45kW-160kW); B3 mounting flange, IP65 protection class, optimized sealing system to prevent dust and oil leakage, for industrial-grade single screw extruders |

3. Customized Extruder Gear Units (Large-Scale High-Torque)

| Model | Weight | Motor Combination (Power Range) |

| EX-HH22, EX-HH28 | 1200kg-2500kg | FLENDER MOTOX integrated IE4 motors (200kW-630kW); transmission ratio 6.3:1-11.2:1, rated torque up to 400kNm, suitable for large-scale plastic extrusion production lines |

| EX-H2SH16, EX-H2SH20 | 850kg-1100kg | Custom high-torque IE4 motors (160kW-400kW); oil cooling system, FEM-optimized housing, for chemical and rubber high-temperature extrusion scenarios |

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}