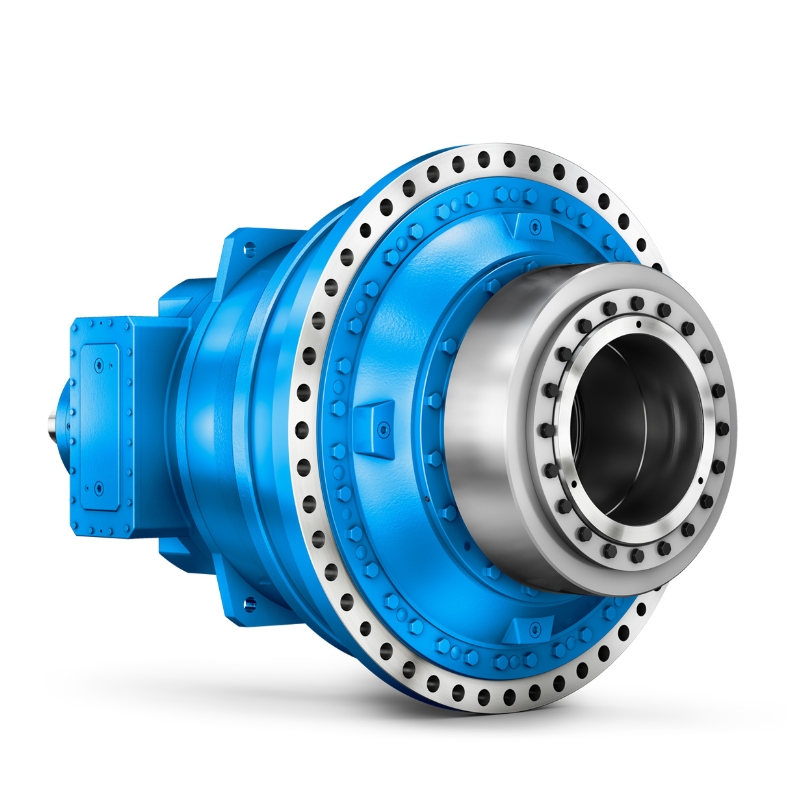

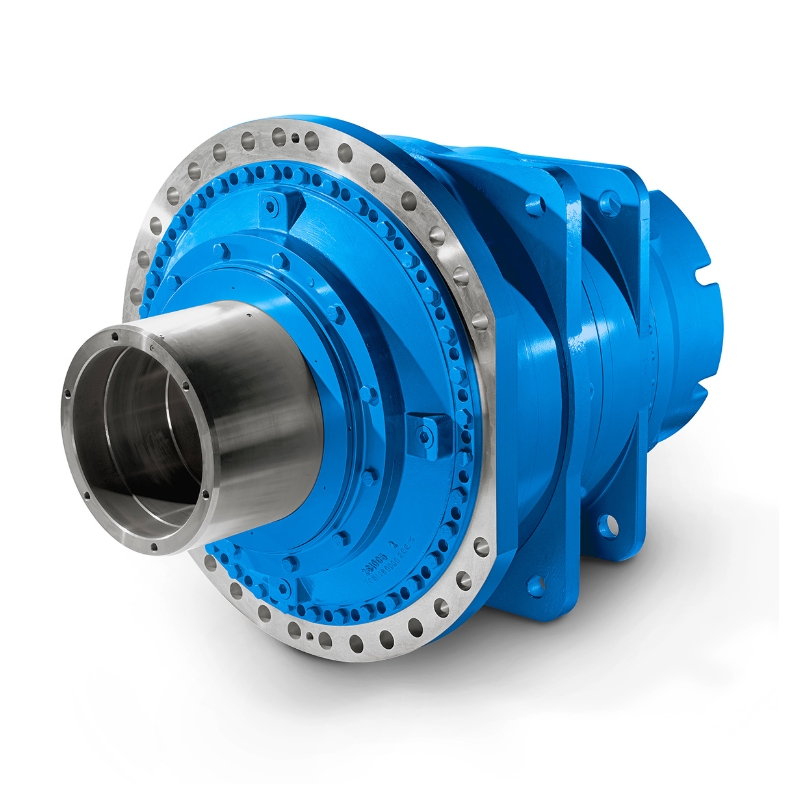

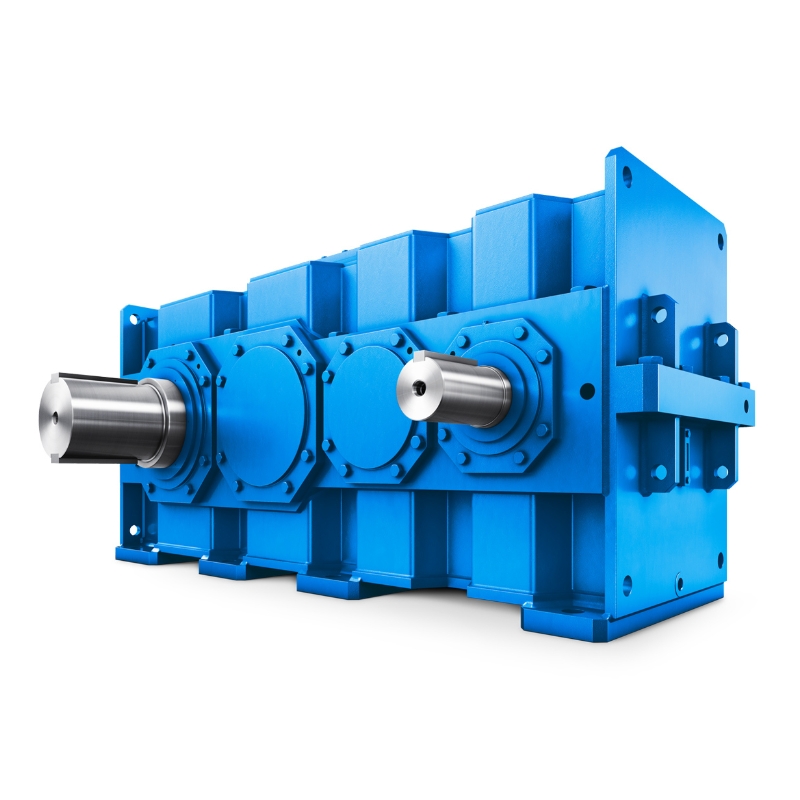

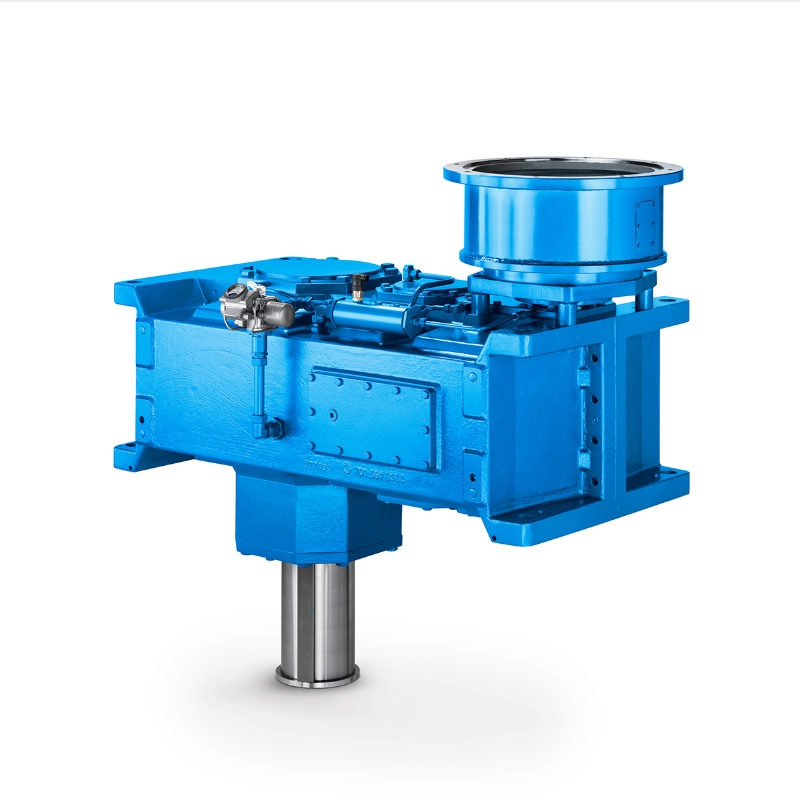

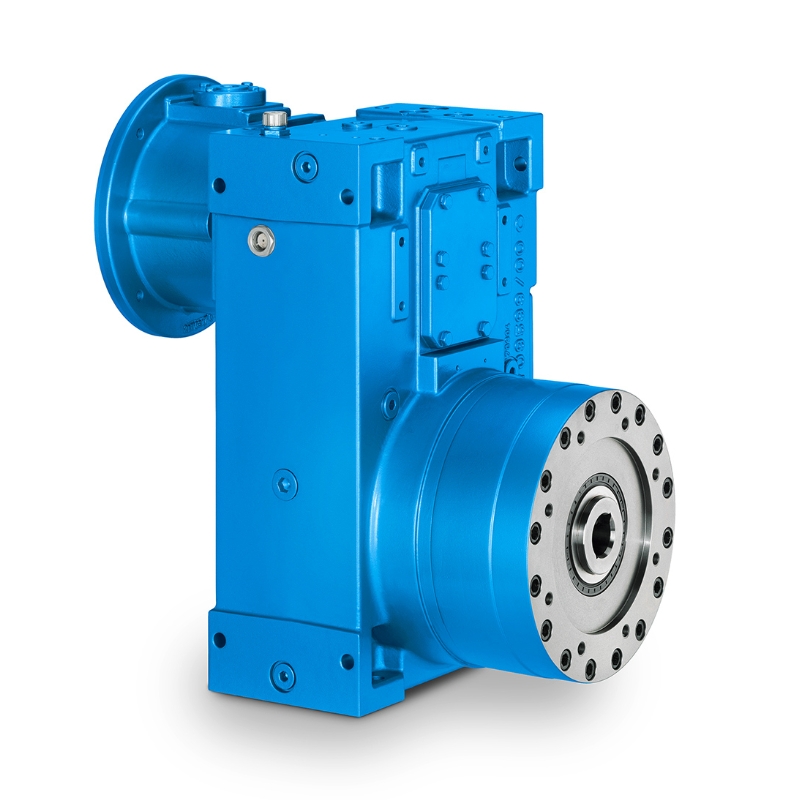

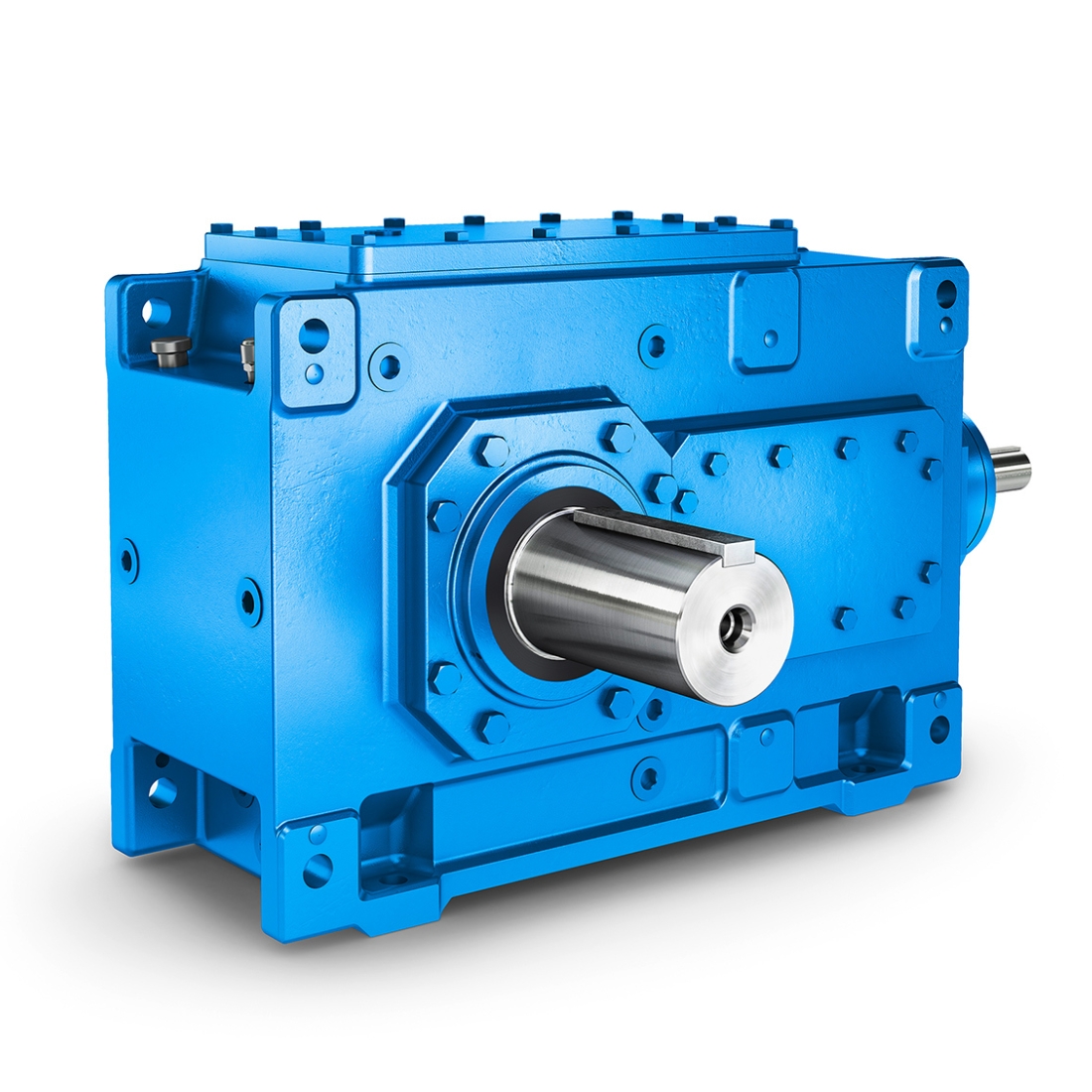

PLANUREX 3 Standard Series

The PLANUREX 3 Standard Series, developed by FLENDER, represents a new generation of high-power-density, multi-purpose premium planetary gear units, setting new benchmarks in quality, flexibility and operational reliability for industrial drives. As a fully standardized product portfolio, it balances power density, equipment availability and cost efficiency optimally, with global short delivery times and excellent cost-performance ratio.

Available in 10 sizes, the series covers a nominal torque range of 1.7MN·m to 5.45MN·m and a transmission ratio range of 26 to 112. Boasting 17.2% higher torque density than its predecessor, it achieves class-leading efficiency with a compact design, enabling space-saving deployment of high torque and large transmission ratios. All sizes can withstand overloads up to twice the nominal torque, ensuring stable operation even under discontinuous loads.

Featuring high modularity, it offers diverse options for application adaptation, including torque shaft support, reinforced bearings, oil cooling connections and low-temperature compatibility down to -40℃. Integrated into Siemens Integrated Drive Systems (IDS), it realizes seamless matching of motors, couplings and lubrication systems for efficient operation.

Widely applied in mining, cement and raw material extraction, it excels as a drive for roller presses and tube mill central drives. Optional smart sensors enable real-time condition monitoring, supporting predictive maintenance and boosting long-term operational stability.

FLENDER Reducer PLANUREX 3 Standard Series Models, Weights and Motor Combinations

Note: The series includes 17 sizes divided into L and XL categories, with rated torque ranging from 480,000N·m to 5,450,000N·m and transmission ratio from 45:1 to 110:1. Weights refer to the gear unit body (welded steel housing) and vary by configuration. Motor combinations comply with FLENDER standard matching, covering IE2-IE4 efficiency classes for heavy-duty industrial applications.

1. PLANUREX 3 L Series (Medium Torque, Horizontal Mounting)

| Model | Weight | Motor Combination (Power Range) |

| P3L-N, P3L-K, P3L-L | 3,800kg-5,200kg | IE3/IE4 motors (160-400kW); compatible with Siemens 1LE1 series, matching solid/hollow shaft configurations, suitable for conveyors and mixers |

| P3L-M, P3L-P, P3L-Q | 5,300kg-6,800kg | IE4 high-efficiency motors (250-500kW); supports oil cooling system, for heavy axial/radial load scenarios like crushers |

| P3L-R, P3L-S, P3L-T | 6,900kg-7,950kg | FLENDER MOTOX integrated motors (315-630kW); -40°C low-temperature compatible, ideal for offshore industrial equipment |

2. PLANUREX 3 XL Series (Ultra-High Torque, Horizontal Mounting)

| Model | Weight | Motor Combination (Power Range) |

| P3XL-N, P3XL-K, P3XL-L | 8,600kg-9,500kg | IE3/IE4 motors (400-710kW); torsionally rigid housing, FEM-optimized, for large-scale rolling mills |

| P3XL-M, P3XL-P, P3XL-Q | 9,600kg-10,950kg | High-power IE4 motors (500-800kW); double overload capacity, compatible with hydraulic auxiliary drives, used in grinding mills |

| P3XL-R, P3XL-S, P3XL-T | 11,000kg-12,750kg | IE4 motors (630-1000kW); integrated temperature monitoring, suitable for extreme heavy-load industrial scenarios |

| P3XL-U, P3XL-V, P3XL-W | 12,800kg-16,950kg | Custom high-torque motors (800-2240kW); shrink disk connection, for super heavy-duty equipment like large crushers |

3. PLANUREX 3 Integrated Power Unit Series

| Model | Weight | Motor Combination (Power Range) |

| P3L-MOTOX, P3XL-MOTOX | 4,500kg-10,200kg | Integrated FLENDER MOTOX IE4 motors (200-630kW); seamless matching, compact design, built-in vibration monitoring |

| P3L-HYD, P3XL-HYD | 5,000kg-11,000kg | Integrated hydraulic motors (160-500kW); for scenarios requiring stepless speed regulation and high torque output |

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}