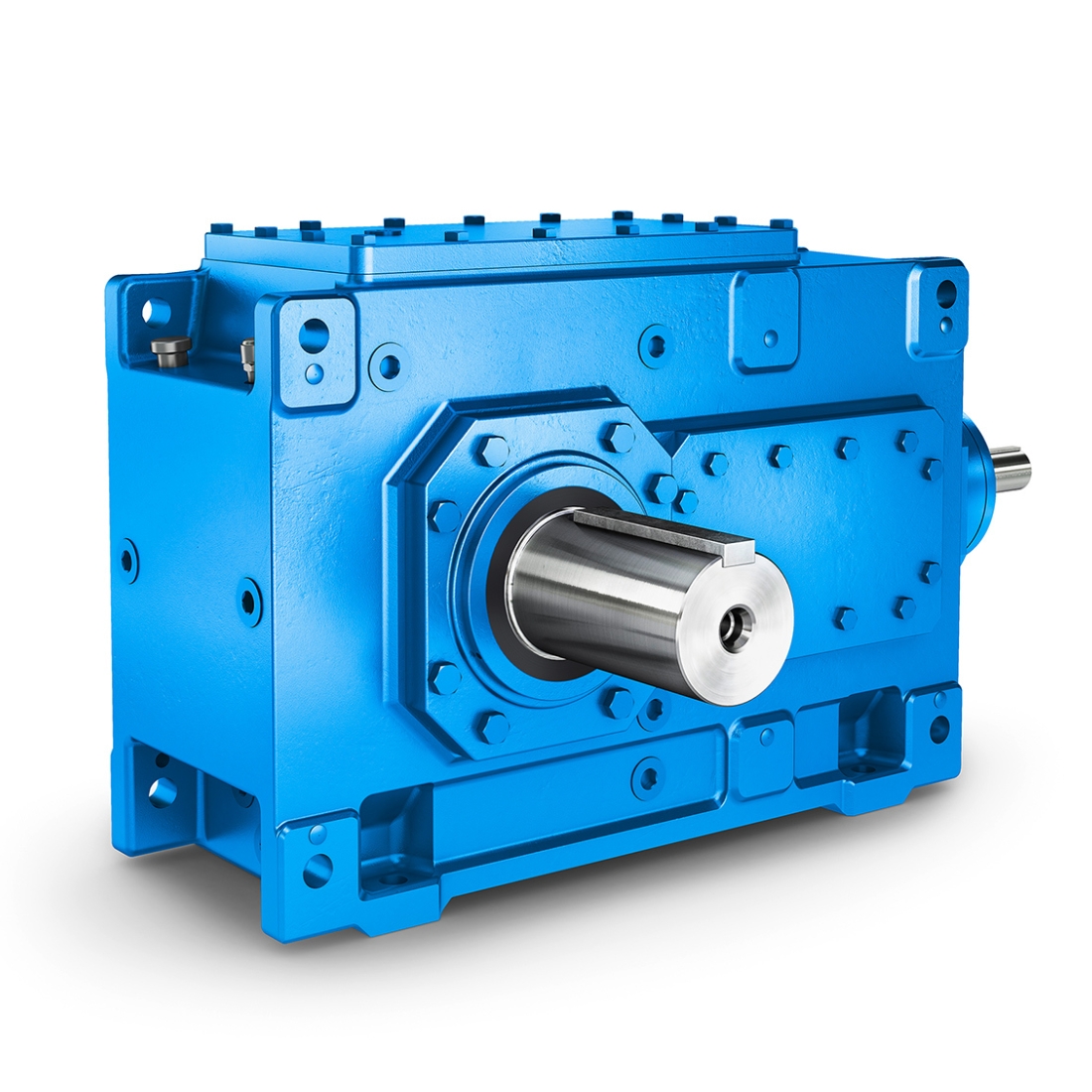

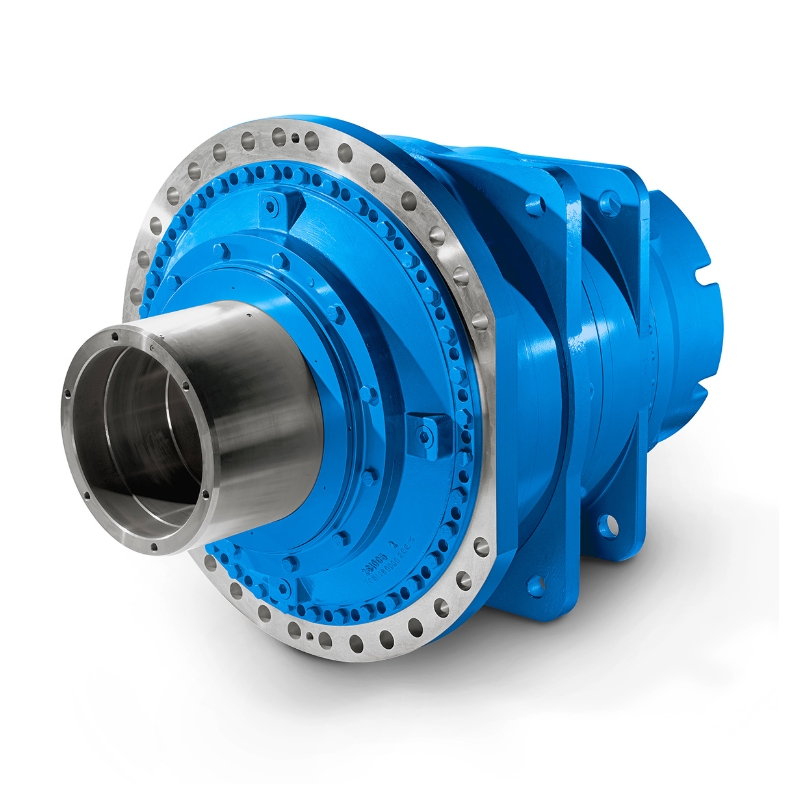

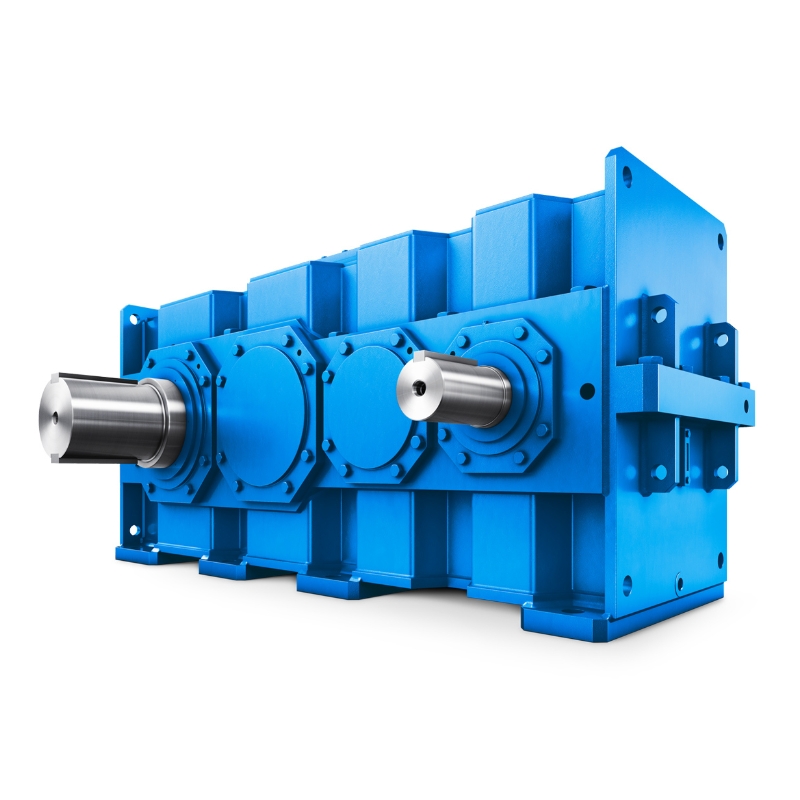

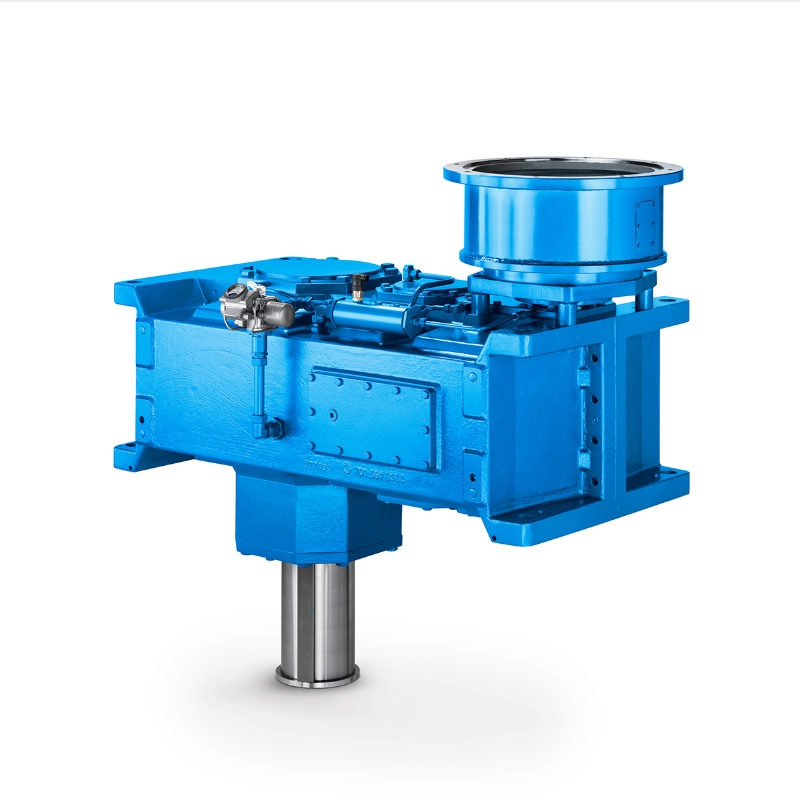

Helical Gear Units and Bevel-Helical Gear Units

Helical gear units and bevel-helical gear units are core mechanical transmission components, widely applied in industrial systems for efficient power and torque transfer, each with unique structural and performance advantages.

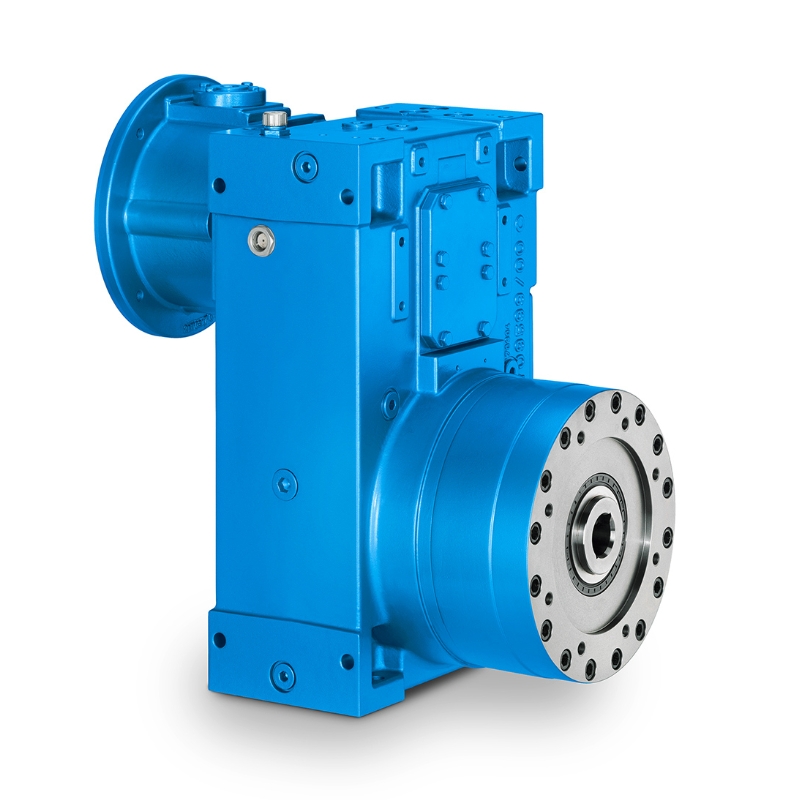

Helical gear units feature teeth cut at an angle to the gear axis, forming a helix shape. This design enables gradual tooth engagement, distributing loads over multiple teeth to reduce noise and vibration significantly. With parallel shaft arrangement, they boast high transmission efficiency (94%-96%) and robust load-bearing capacity, suitable for high-speed, continuous-duty scenarios. Common applications include industrial machinery, automotive transmissions, and wind turbine high-speed stages, though they generate axial thrust requiring specialized bearings and have higher manufacturing costs due to complex processing.

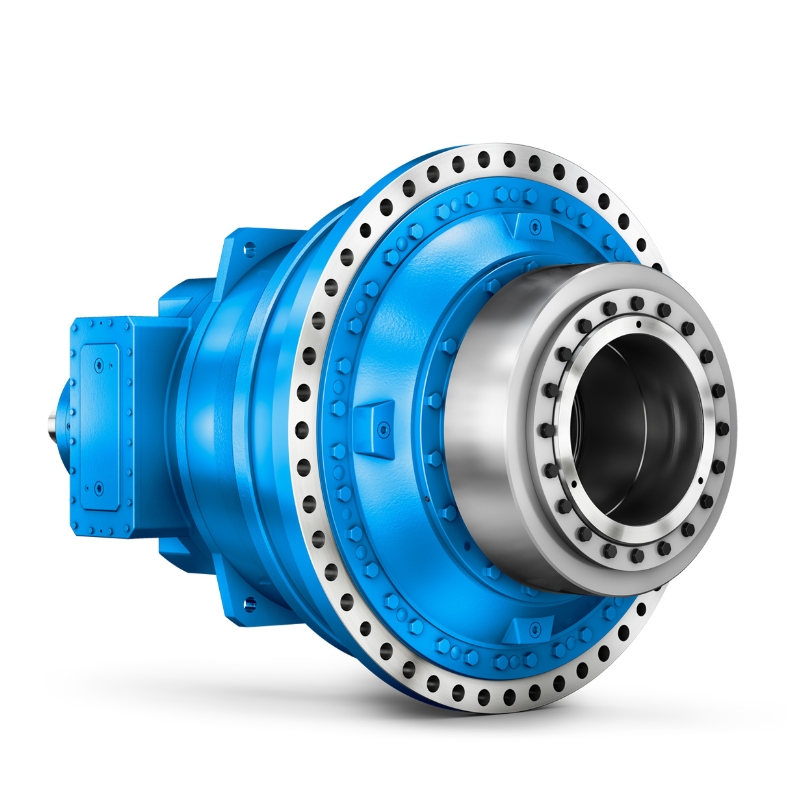

Bevel-helical gear units integrate helical teeth with conical gear structures, enabling power transmission between intersecting shafts (typically 90°). They inherit helical gears’ smooth operation and combine bevel gears’ directional adjustment capability, achieving over 95% efficiency and 20%-30% higher load capacity than straight bevel gears. Available in configurations like constant-mesh and dual helical, they adapt to diverse demands from precision robotics to heavy-duty mining equipment. Their compact design suits space-constrained settings, though installation requires high alignment accuracy.

Both units are indispensable in modern industry: helical units excel in parallel-shaft high-speed transmission, while bevel-helical units dominate angular, heavy-load applications, jointly supporting the stable operation of industrial machinery worldwide.

FLENDER Helical Gear Units and Bevel-Helical Gear Units Models, Weights and Motor Combinations

Note: FLENDER helical and bevel-helical gear units are modular industrial transmission components, widely applied in conveyors, bucket elevators, water turbines and heavy-duty machinery. Helical gear units feature parallel shaft transmission with high efficiency, while bevel-helical units offer right-angle output for space-saving layouts. All models adopt hardened ground gears (tooth surface hardness HRC54-62) and rigid cast iron/welded steel housings. Weights refer to the gear unit body and vary by mounting type; motor combinations comply with FLENDER standards, covering IE2-IE4 efficiency classes, with power ranges 2.2kW-4400kW and torque up to 900kNm.

1. Helical Gear Units (H Series, Parallel Shaft)

| Model | Weight | Motor Combination (Power Range) |

| H1-H8 | 25kg-380kg | IE3/IE4 motors (2.2kW-75kW); 1-2 stage transmission, efficiency ≥96%, suitable for light-medium load conveyors |

| H9-H16 | 420kg-1200kg | IE4 motors (90kW-250kW); 2-3 stage, hollow/solid shaft options, IP65 protection, for industrial mixers |

| H17-H26 | 1300kg-4500kg | FLENDER MOTOX integrated IE4 motors (315kW-450kW); 3-4 stage, oil cooling system, for heavy-duty bucket elevators |

2. Bevel-Helical Gear Units (B Series, Right-Angle Shaft)

| Model | Weight | Motor Combination (Power Range) |

| B2SH04-B2SH18, B2SV04-B2SV18 | 45kg-520kg | IE3/IE4 motors (5.5kW-160kW); 2-stage, ratio 5-14, horizontal/vertical mounting, for small water turbines |

| B3SH04-B3SH26, B3SV04-B3SV26 | 580kg-1800kg | IE4 motors (110kW-400kW); 3-stage, ratio 12.5-90, reinforced bearings, for heavy-load conveyors and mixers |

| B4SH05-B4SH26, B4SV05-B4SV26 | 1900kg-4800kg | High-power IE4 motors (450kW-4400kW); 4-stage, ratio 80-400, torque up to 900kNm, for extreme heavy-duty machinery |

3. Standard Integrated Gear-Motor Units

| Model | Weight | Motor Combination (Power Range) |

| B3DH15, B3DV15, B3HH15 | 320kg-650kg | Integrated IE4 motors (75kW-200kW); bevel-helical structure, compact design, for dryer section drives and screw drives |

| B3SH15, B3SV15, B3SM15 | 380kg-720kg | Integrated IE4 motors (90kW-250kW); multi-mounting options, low noise ≤85dB, for general industrial transmission |

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}