FLENDER Gear Unit for Aerator

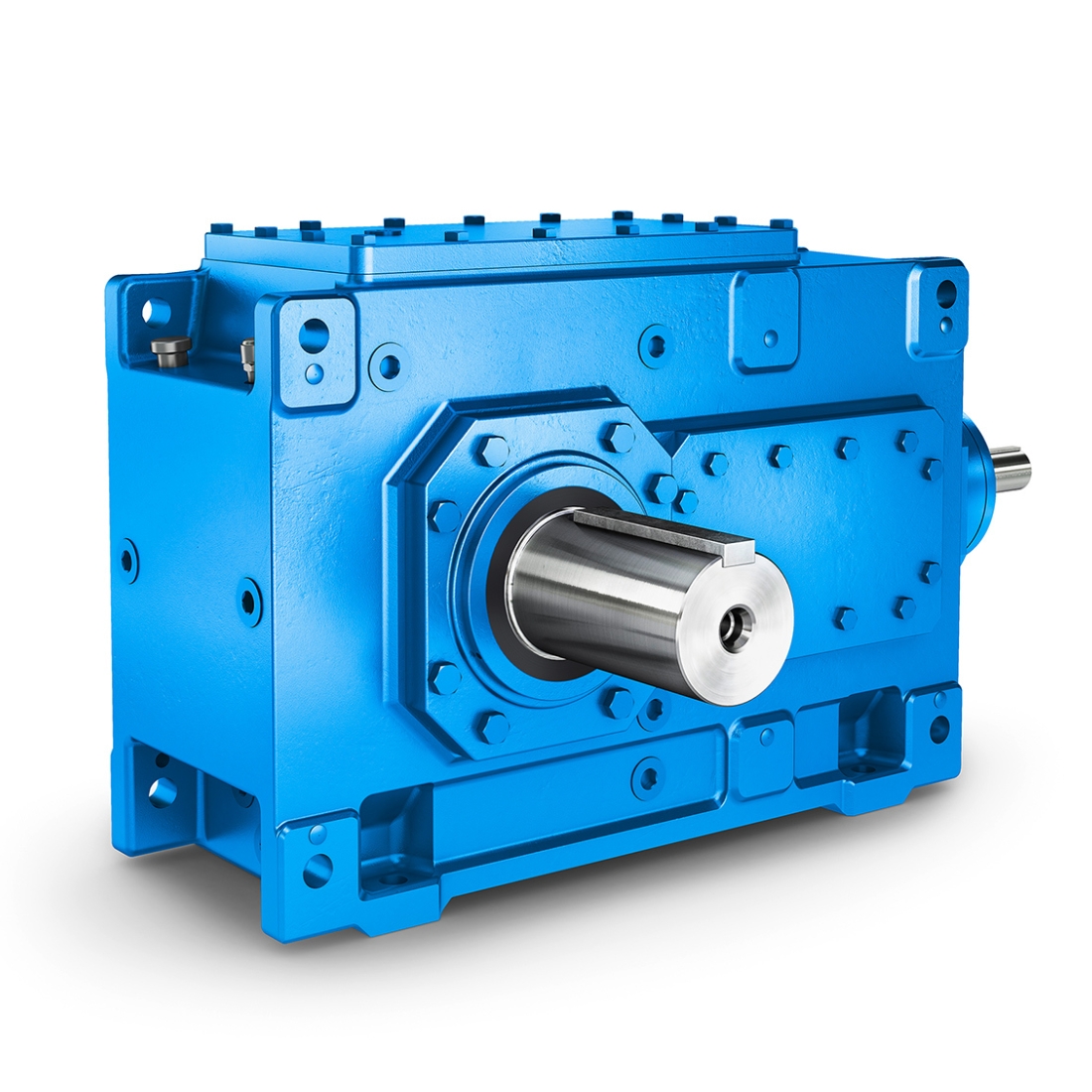

As a core drive component for wastewater treatment aerators, FLENDER Gear Unit for Aerator is engineered to deliver reliable and efficient performance in harsh aquatic environments. Specifically designed for aeration systems that enrich water with oxygen to activate bacteria and decompose sludge, this gear unit ensures stable power transmission for impeller operation, which is critical for biological wastewater treatment processes.

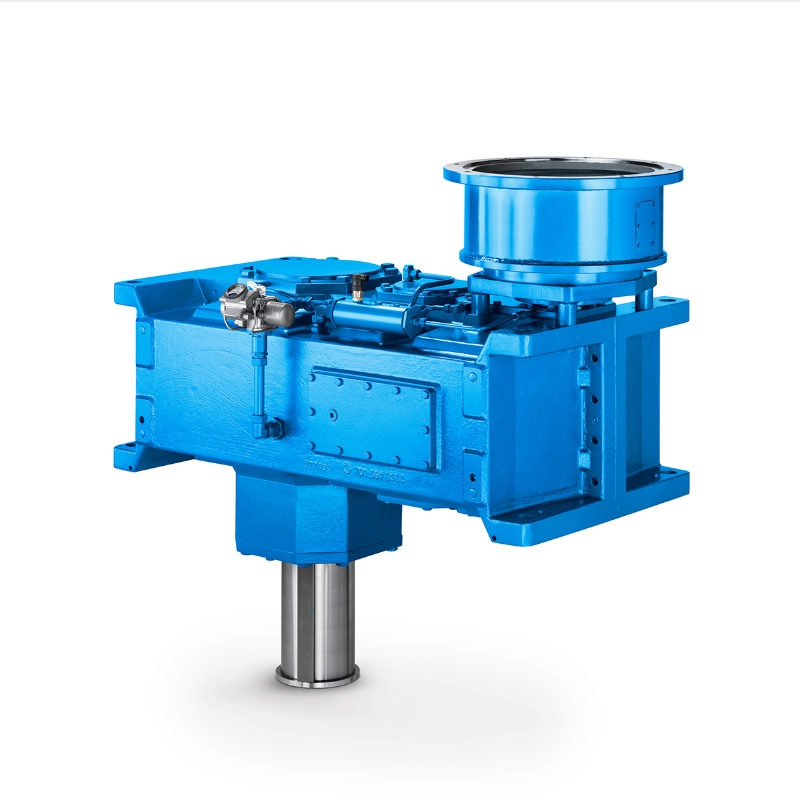

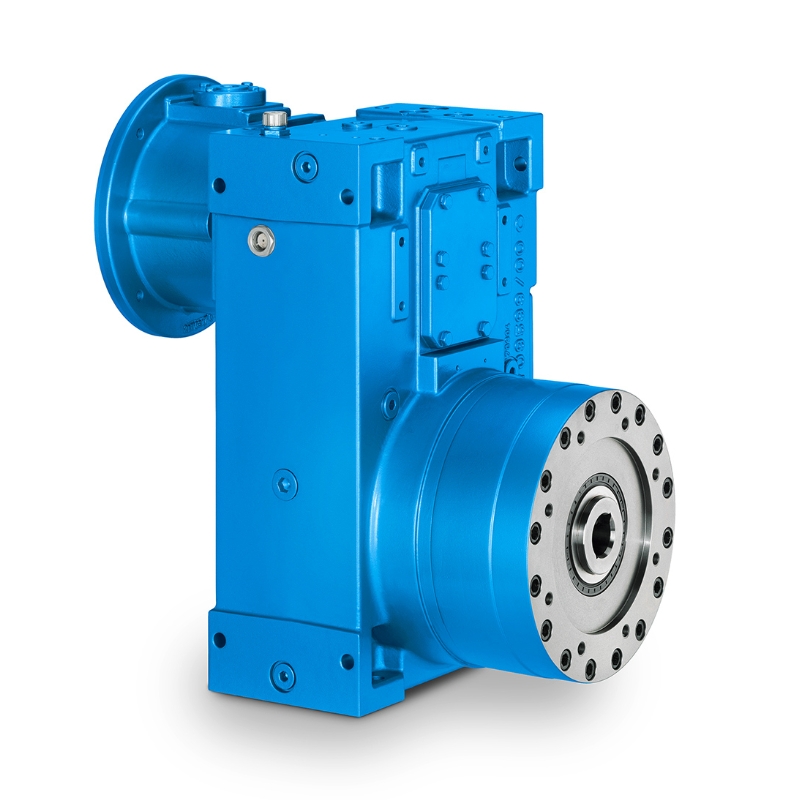

The gear unit features a vertical mounting design, with its output shaft extending downward to connect the aerator impeller. A key innovation is its dry well structure, equipped with an oil retaining tube and non-contacting, wear-free shaft seal. This design completely prevents gear oil leakage, avoiding water contamination and safeguarding water quality in treatment facilities.

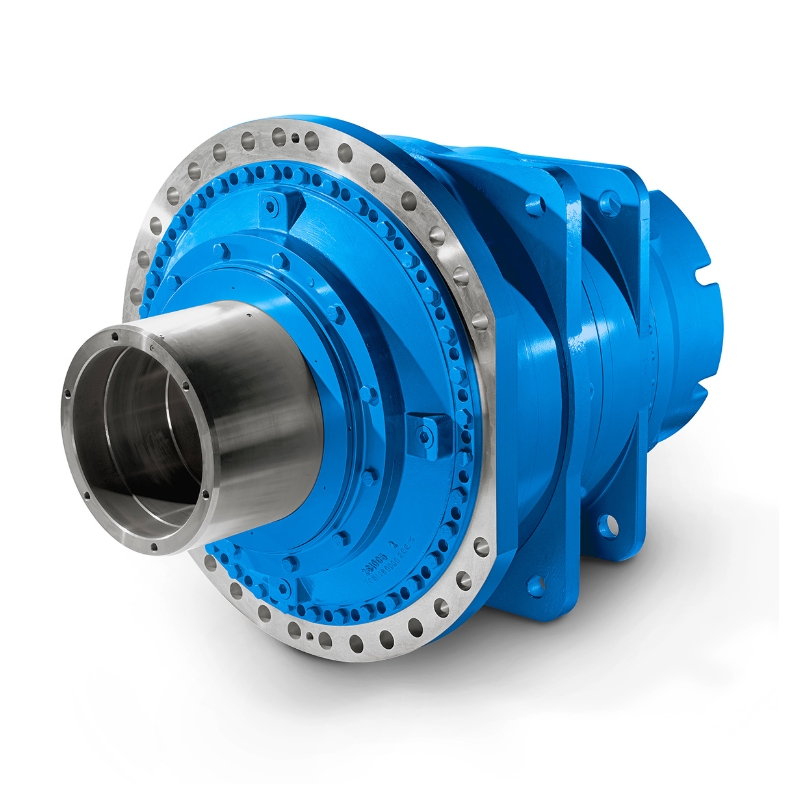

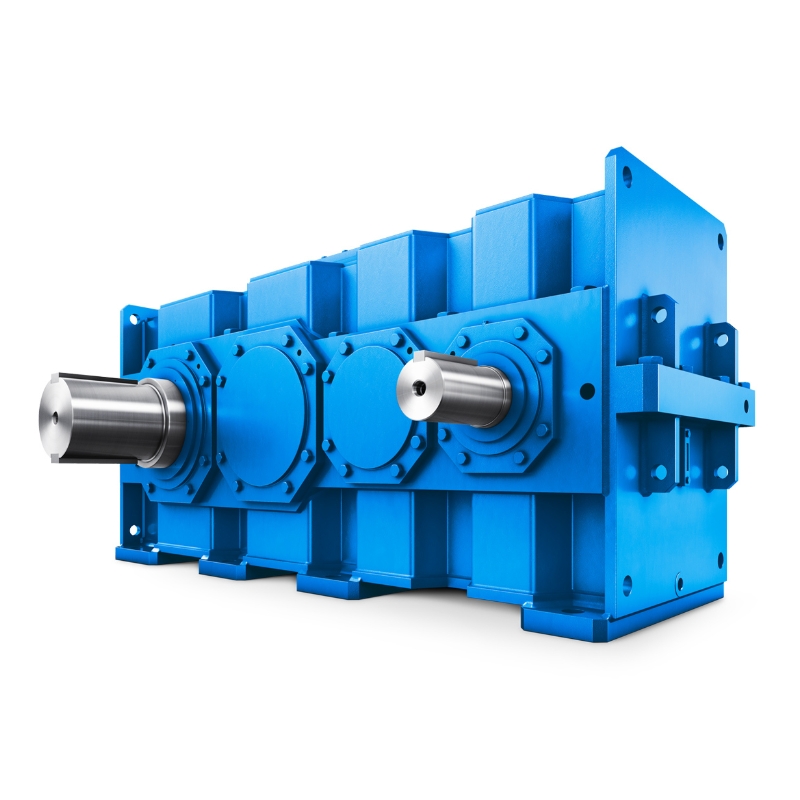

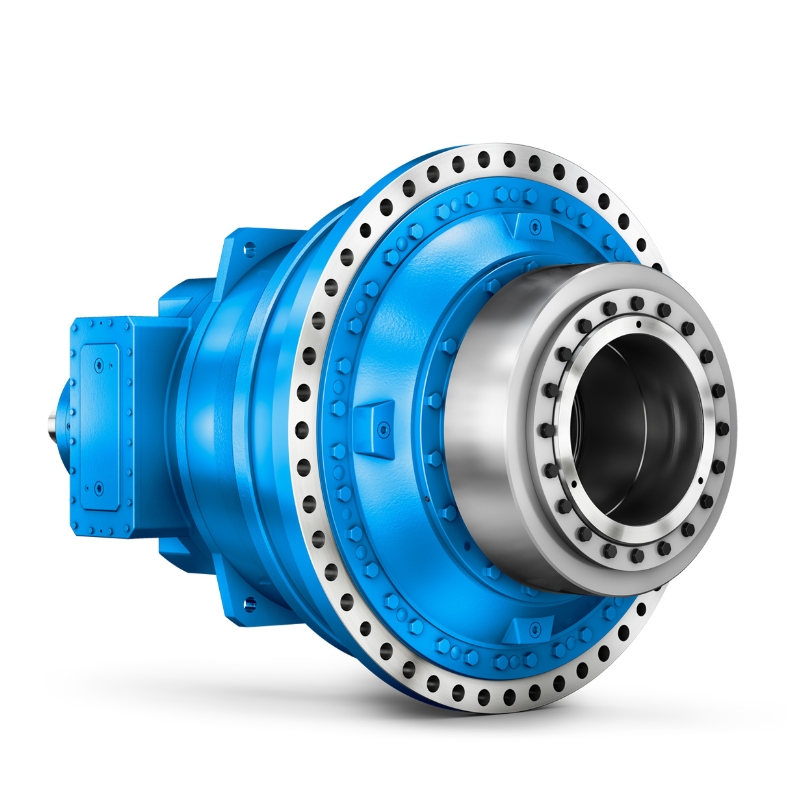

Constructed with extra-heavy-duty output shafts and reinforced bearings, it effectively absorbs axial and lateral loads generated during aeration, enhancing operational stability. It offers two types of gear configurations—helical and bevel-helical, with 2 to 3 stages and 16 size options. Technical parameters cover power ratings up to 3,600 kW, transmission ratios ranging from 6.3 to 112, and nominal torques between 10.5 to 173 kNm, adapting to diverse aerator requirements.

Equipped with flanged-on pump for oil pressure lubrication, it maintains high efficiency and low noise levels. Its modular design allows easy integration with aerators via a dedicated coupling flange, ensuring quick installation and maintenance. With high operational reliability and efficiency, it has become a preferred choice for municipal and industrial wastewater treatment plants globally.

Beyond wastewater treatment, it also suits scenarios requiring stable vertical drive, embodying FLENDER’s advantages in integrated mechanical and electrical drive systems—combining technological leadership, durability, and cost-effectiveness to support sustainable water treatment solutions.

FLENDER Reducer Gear Units for Aerator Models, Weights and Motor Combinations

Note: The weights refer to the reducer body (high-strength cast iron or welded steel housing) and may vary with accessories (e.g., waterproof sealing, anti-corrosion coating) and output configurations. Motor combinations comply with FLENDER standard matching for aerator scenarios, covering IE2-IE4 efficiency classes, suitable for centrifugal aerators, surface aerators and submersible aerators in wastewater treatment plants. The transmission efficiency is ≥95%, and the design is optimised for continuous operation under humid, corrosive conditions with low noise and high reliability.

1. HH Series (Hardened Helical Gear Units for Aerators)

| Model | Weight | Motor Combination (Power Range) |

|---|---|---|

| B3HH12B | 380kg | IE3/IE4 three-phase asynchronous motors (45-75kW); input speed 1500r/min, output speed 21.39r/min, compatible with B3 mounting flange, suitable for surface aerators, matching Siemens 1LE1 series motors with IP65 protection class for humid environments |

| B4HH15A | 520kg | IE4 high-efficiency motors (75-110kW); input speed 1486r/min, reduction ratio 85.65:1, output speed 17.35r/min, designed for large-capacity centrifugal aerators, with reinforced bearings for axial load resistance |

| B4HH15C | 535kg | IE3 motors (90-132kW); same reduction ratio as B4HH15A (85.65:1), compatible with frequency conversion control for stepless speed regulation, optimised sealing system to prevent water and sludge intrusion, suitable for wastewater treatment projects |

2. H2 SH Series (Compact Helical Gear Units for Small Aerators)

| Model | Weight | Motor Combination (Power Range) |

|---|---|---|

| H2 SH 07 A | 528g | IE4 motors (44kW); input speed 1500r/min, suitable for small integrated aerators in sewage treatment equipment, recommended ISO VG 320 synthetic extreme pressure gear oil, with BA5010/BA7300 certifications |

3. Customised Aerator Gear Units

| Model | Weight | Motor Combination (Power Range) |

|---|---|---|

| AER-HH18 | 780kg | IE4 high-power motors (132-160kW); designed for submersible aerators, waterproof and anti-corrosion structure, matching flame-proof motors for hazardous environments, transmission torque up to 50,000N·m |

| AER-H2SH10 | 8.5kg | IE3 motors (1.5-4.0kW); compact design for small aerators, low noise operation (≤75dB), compatible with vertical installation, suitable for laboratory or small-scale wastewater treatment devices |

CUSTOMER REVIEWS

{{commentStat.total}} Revirews

{{item.comments}}